1.A connecting hyperlink of an O-ring Chain for standard application is pre-coated with grease at the pins. Prior to connection, verify the grease around the surfaces of pins, and should the quantity of grease is smaller, apply grease with bare hands. (If gloves are utilized, the grease might be absorbed through the gloves.)

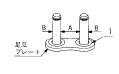

Illustration: When the connecting website link (I) of an O-ring chain for common application is

shipped, O-rings are fitted with the roots of the pins. When the O-rings come loose because of vibration in the course of transport, refit the O-rings in on the roots of the pins.

In this case, make sure to return the grease collected in the roots of your pins on the central surfaces from the pins, a lot more at portion A than at portions B proven in the above illustration. (Portions A is worn on account of sliding using the bushings.)

2.The chain is usually most conveniently linked on the teeth of the sprocket. Engage the back links at the two ends from the chain together with the sprocket teeth and match connecting pins. If the sprocket is usually moved, the chain may also be linked around the loosened side.

three. Connecting process

1.Confirm that O-rings are connected towards the roots of the pins.

two.If the quantity of grease applied on the connecting pins is smaller, coat the pins with grease with the central portions.

3.Insert the connecting pins in to the bushings with the inner links at each ends.

4.Verify that the grease is applied to the total encounter from the O-ring, and fit the O-ring onto the connecting pins.

five.Insert the connecting pins into the connecting

6.You’ll want to confirm that the spring clip is securely fitted from the clip grooves of your connecting pins.

This completes jointing with the connecting hyperlink. Note that grease around the surfaces of connecting pins and O-rings may be removed throughout installation do the job. In this case, re-grease employing the grease on the surface of your base chain or the grease within the polyethylene bag by which the connecting link was contained.

Tips on how to connect O-ring Chains Remarks to connect common O-ring Chains

Tags: