EPG has been successfully certified by ISO9002 Quality Management System, ISO9001 Quality Management System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management system.

Overview

Quick Details

- Applicable Industries:

Manufacturing Plant

- Brand Name:

OEM

- OEM Service:

Support.

- Tolerance:

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment. 0.01-0.05mm or Customized.

- Quality Certify:

ISO9001, SGS

- Surface Treatment:

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

As Customers' Request

- Equipment:

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Service:

Customized OEM CNC Machining

- Drawing Format:

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 100000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

- Lead Time

: Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

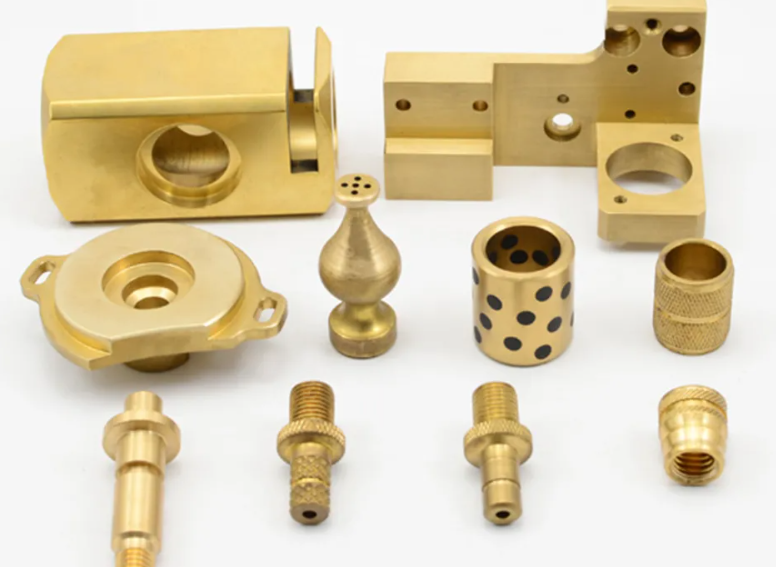

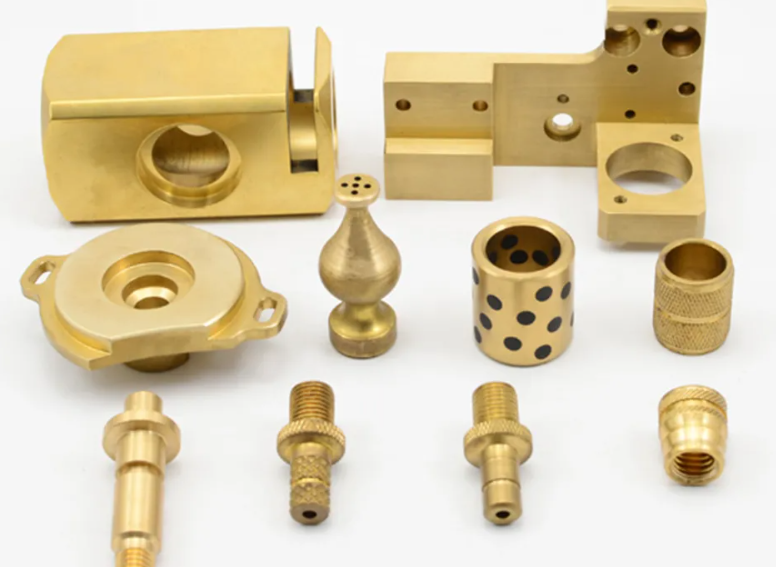

Product Description

Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers' requirements |

Surface Treatment | Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

Dimension | As customers' request |

Service Project | To provide production design, production and technical service, mould development and processing, etc |

Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication… |

Packing | * Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes |

Trial sample time | 7-10 days after confirmation |

Delivery time | 7-30 days after receive the pre-payments |

Payment Terms | T/T,Western Union,Paypal |

Products Show

Company Information

Ningbo Target IMP. &EXP. CO. LTD. is located in ningbo, Target company has 800 square meters of plant area and 18 professional technical workers. The Annual out put of Target company is 5 million. We provide our customers with a variety of customized machining machinery parts service.

Our production equipment includes the following types:

1)6 sets cnc machining center(including 3 sets Four axis cnc machining center and 3 sets three axis cnc machining center)

2)3 sets CNC milling machine

3)16 sets CNC lathe

4)4 sets drilling machine

We also have outsourcing factories with very good cooperation. These factories can supply welding parts, casting parts, stamping parts, bending parts with very good price.

We warmly welcome you to our company and hope to provide the service for you.

Processing Equipment

Testing Equipme”EPG” branTECHNOLOGY LEADER IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for over 30 years now. This great determination has helped us become an undisputed global technology and quality leader.d rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People's Republic of China. nt

Packing & Delivery

FAQ

Q: How to enjoy OEM service?

A: Usually, according to your design drawings or original samples, we provide some technical Suggestions and quotes to you. we will arrange production after you confirm.

Q: When can I get the quotation and information?

A: Our team will Reply within 12 hours.

Q: How long can I have the sample?

A: Depending on your products and request, it usually takes 7-10 days.

Q: What are acceptable types of drawings ?

A: 2D drawings: PDF, CAD, JPG, etc.,

3D drawings: STP, IGS, STL, SAT, PRT, IPT, etc.

Inquiry Now

Contact Person | Bridget Woo |

sales2(at)ningbotarget.com | |

Office Telephone | 86-571-56280173 |

Fax | 86-571-56280172 |

Mobile Phone | 86-18888795249 |

Skype | +8618888795249 |